project summary

The outcome of this project is a horizontal bike 'flag' that is retractable, blends with the bicycle and functions a rear fender when folded away. It's purpose is to help communicate to car drivers that they should adhere to the passing distance rules for bicycles on the road.

Duration: September 2021 - April 2022

Key skills used: Research, Interviews, Survey creation, Concept sketching, Presentations, 3D printing

Key apps used: Miro, Photoshop, Illustrator, Indesign, Solidworks, Keyshot

The problem

The poor weather in Ottawa’s winters highlights what the main North American issue is: Poor bike infrastructure, maintenance and design. This makes bicycle commuters have to use the roads with cars at points in their commute, making them feel unsafe.

The goal

With the main problem defined, the goal of this project was to design a product and/or system, that allows bicycle commuters in North America to feel safer during the parts of their commutes that they have to share the road with cars.

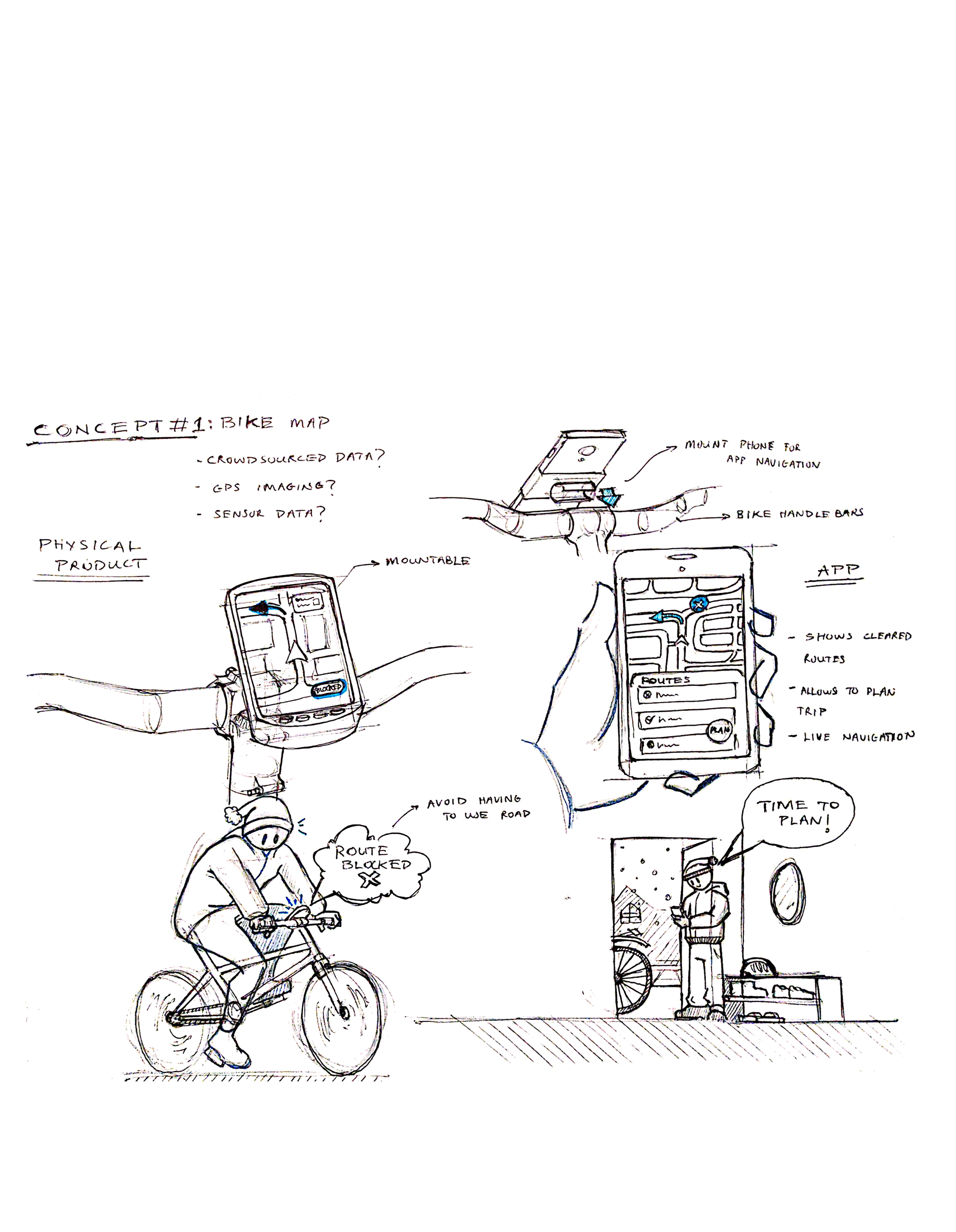

concepts

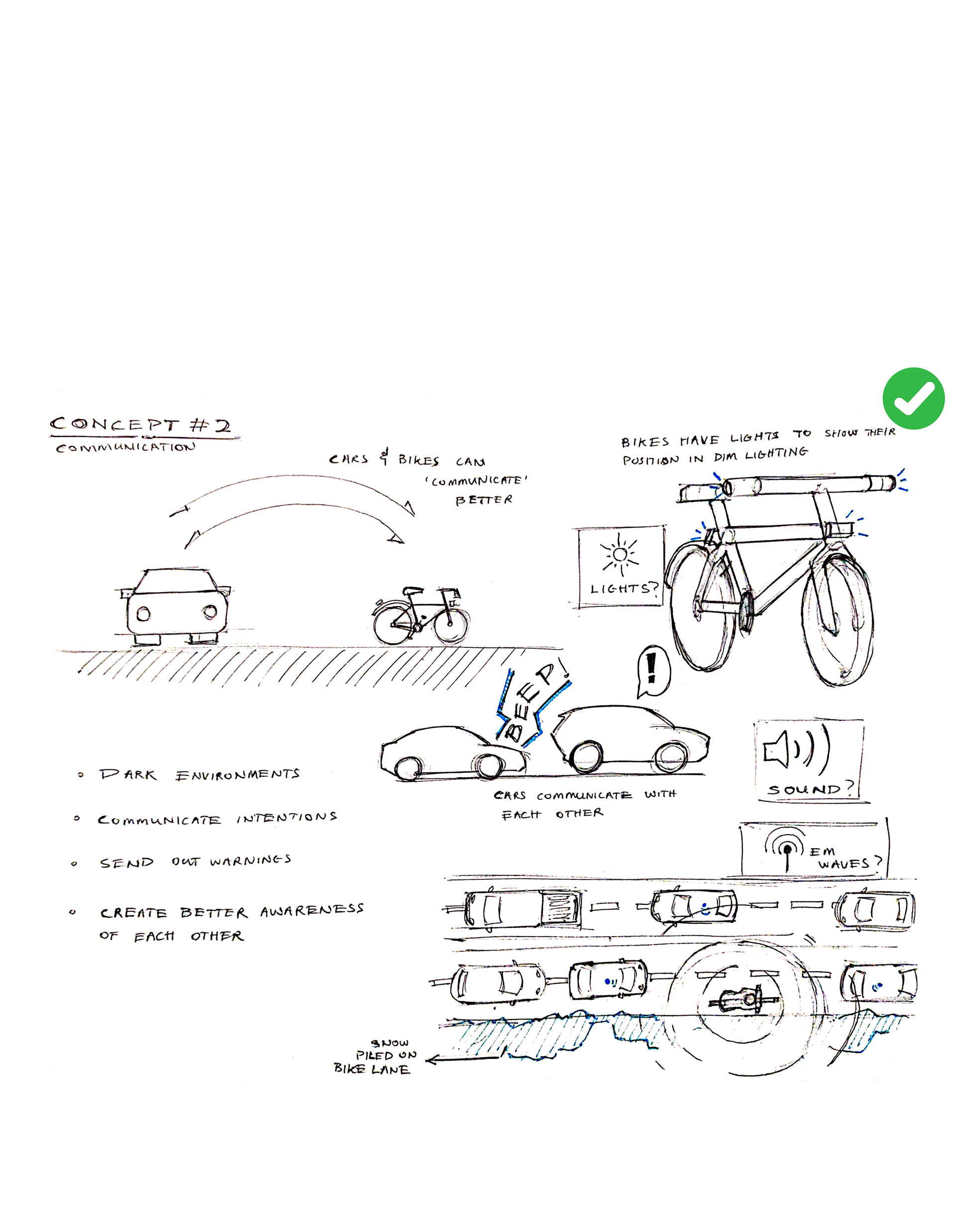

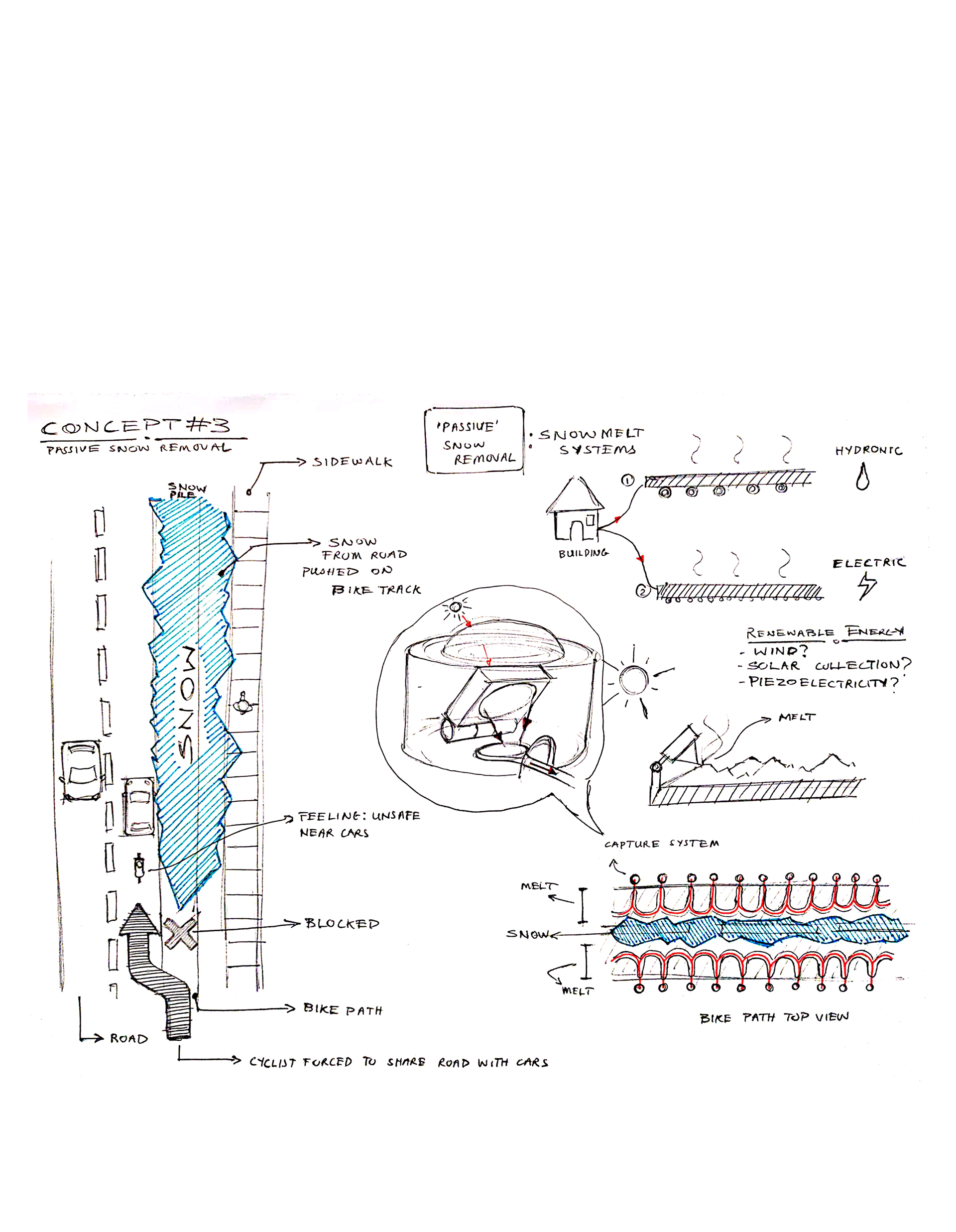

With the goal defined, Miro was used to brainstorm ideas, and 3 main concepts were formed. These were fairly broad concepts with one of them needing development.

understanding the user- The need for space

Secondary and Primary research showed that bike commuter's lack of space is an issue when it comes to feeling safe among cars. They need some sort of space from cars to feel safe during their commutes.

Insights from the interviews conducted also brought about a 'predator-prey' analogy, with the prey representing bicycle commuters who avoid the 'territory' of cars, who could be likened to a predator or a dangerous presence.

The new problem was therefore: In communities or cities where the infrastructure fails to adapts to their need for space away from cars at an appropriate rate, how can they communicate this need for space to car drivers on the road?

Preliminary concept- reactive Laser barrier

With a need for space from cars being identified as a major problem, concept 2 was chosen as most the appropriate idea to be developed.

Through a bit more brainstorming, the idea to use laser projections to communicate the bicycle commuter's ideal safe space on the road was formed.

The laser barrier concept was a design that aimed to bring the bicycle commuters' vision of their personal safety bubble to reality. It would detect and react to cars as they approach; a feature inspired by how animals like rattlesnakes give warnings to threats, to more effectively communicate that they should stay out of the users' space.

The users' perceived safe space is projected onto the road. If a car is getting too close to invading this space, the projected lights change colour to warn the car driver. Getting even closer causes a warning sound to activate.

laser barrier fails to meet requirements (need new solution)

By testing similar existing products, it was found that using a laser to project signals and shapes to the ground, is not a very realistic solution, as it did not meet a specification set for the design: The product should work in as many roads and weather conditions as possible

the new solution is... a pool noodle?!

With the laser concept failing to meet enough specifications, a new solution had to be conjured. From primary research, the existence of the use pool noodles to act as a physical indication of a bicycle commuter's safe space was discovered.

The horizontal safety flag

Having an object sticking out from the side of a bicycle may seem like a foreign concept, but it turns out that the practice is recognized in the form of a horizontal safety flag.

According to an Ontario safety book, a horizontal safety flag is an optional equipment that encourages motorists to pass bicycle commuters at a safe distance.

People use pool noodles as horizontal safety flags. They are actually effective according to primary research and Secondary research, so why are they so rare?

With this information acquired, an opportunity was found. There is an opportunity to design a horizontal flag that bicycle commuters can use, without any of the drawbacks that exist in pool noodles and many horizontal flags.

The definitive design- smart fender + Horizontal Flag

After a bit of idea exploration, the design was planned to be based on the form of a detachable bicycle rear fender. This decision was made because rear fenders look natural on bicycles, eliminating the embarrassment problem associated with pool noodles and existing horizontal flags.

This design was to be an electricity powered, automated rear fender that detects cars and can deploy a flag to show passing distance; depending on how close a car gets to the user. Combining the rear fender flag with smart car detection essentially replaces the smart laser boundary with a physical one.

The definitive design- removing automation

By performing more primary research, a few interesting insights were formed:

- People who ride in their cities tend to know the traffic conditions and attitudes of the cars on those roads. INSIGHT: People don’t need a computer to decide when they need the flag up or not.

- People are just as worried about how the flags affect their immediate environment, as the benefits they provide. INSIGHT: The ease or speed of resetting the flag is important as they want to have the ability to get it out of the way if needed.

Insights showed that people did not need an automatic product

It is best that people have full control over when they want the flag out or not, as they know best when they will need it. The flag does not have to be ‘smart’, so it was decided that all sensor features would be removed. The fender would be controlled wirelessly with a front mounted remote.

Now, it is an electronic fender who's flag can be deployed and retracted with the push of a button.prototyping

The prototyping phase involved trying to understand how the fender/ flag would work. In this phase, rough prototypes were made to test concepts, as well as secondary research on components such as motors, batteries, gears, lights, and mechanical systems, to try to make moving the fender electronically as efficiently as possible. Components were also researched to find realistic size estimates of the product.

This rough prototype proved that the concept can mount on the seat post of bicycle, does not interrupt the legs during pedaling, and stays stable in both open and closed states as long as the design is light enough.

After this, a common concern arose...

The decision for which mechanism to use was finalized with a quick material test. This test was done using a thin sheet of Vivak plastic, and a 1:1 scale track mock-up which highlighted the flaws of a more flexible material. This material...

- Is unlikely to be able to remain horizontal when extended

- Potentially puts more strain on the rest of the system during impacts due to the lack of a joint

- May be more difficult to reset when bent/ deformed

- The dimensions of the track did not allow for more stable cross sections

user testing

With the rough prototype made, simple user tests were performed to improve the user experience. The participants were asked to act like they were riding on the road, and evaluate the usability of the prototype.

Note about testing: It was done indoors with simply a bike and no motion. This means not all parameters that would be in play were there, and this may have influenced the responses given and therefore the insights generated.

Test findings

- Nobody really cared for how the safety mechanism worked, rather they did not

want the flag touching their legs. Meaning: The 1st stage of the flag should stay at

90degrees when deployed

want the flag touching their legs. Meaning: The 1st stage of the flag should stay at

90degrees when deployed

- The flag should give feedback of its status, like when it is fully closed, and when it has been hit, as participants would not want to look back while riding. Meaning: There should be some sort of feedback on the state of the flag.

- Manually resetting the flag WHILE MOVING was deemed uncomfortable for the participants. They would rather have something on the cockpit to control it. Meaning: Having a front mounted control for the user to control the deployment of the flag is ideal.

Development: removing electronics

Up until this moment, the product was planned to be electronic, with the main advantage being the convenience of easily controlling the flag's state while riding the bicycle (with a front mounted switch).

However, through continuous prototyping, thinking, and feedback from others, it was decided that electronics should be removed from the product, making it manually operated. The reasons for this decisions are:

- It would make for a less expensive product, making it more accessible to bicycle commuters, some of whom use bicycles because they are relatively inexpensive.

- No electronics means less weight

- Removing electronics removes the need to worry about battery charging, and complicated maintenance

- Having no electronics reduces the number of materials in the product making it easier to breakdown for reuse

- A few of the testing participants suggested that they prefer having a more tangible interaction with the product, with one stating that they would stop riding to ensure that the product was working properly.

Now the product is a detachable rear fender that can serve as a safety flag when needed by the user. It works via a clock spring mechanism and a torsion spring mechanism. Both spring systems keep the flag closed. The user can slow down/ stop riding, then manually open and snap the flag into its open position, performing both motion 1 & 2 (shown below).

Prototypes: verifying decisions

After the removal of electronics from the design, some new things had to be considered in more depth such as the reachability and size of the design with less components. From these quick tests, the conclusion was that the flag could be opened comfortably while the user is on the bicycle (ideally while stationary).

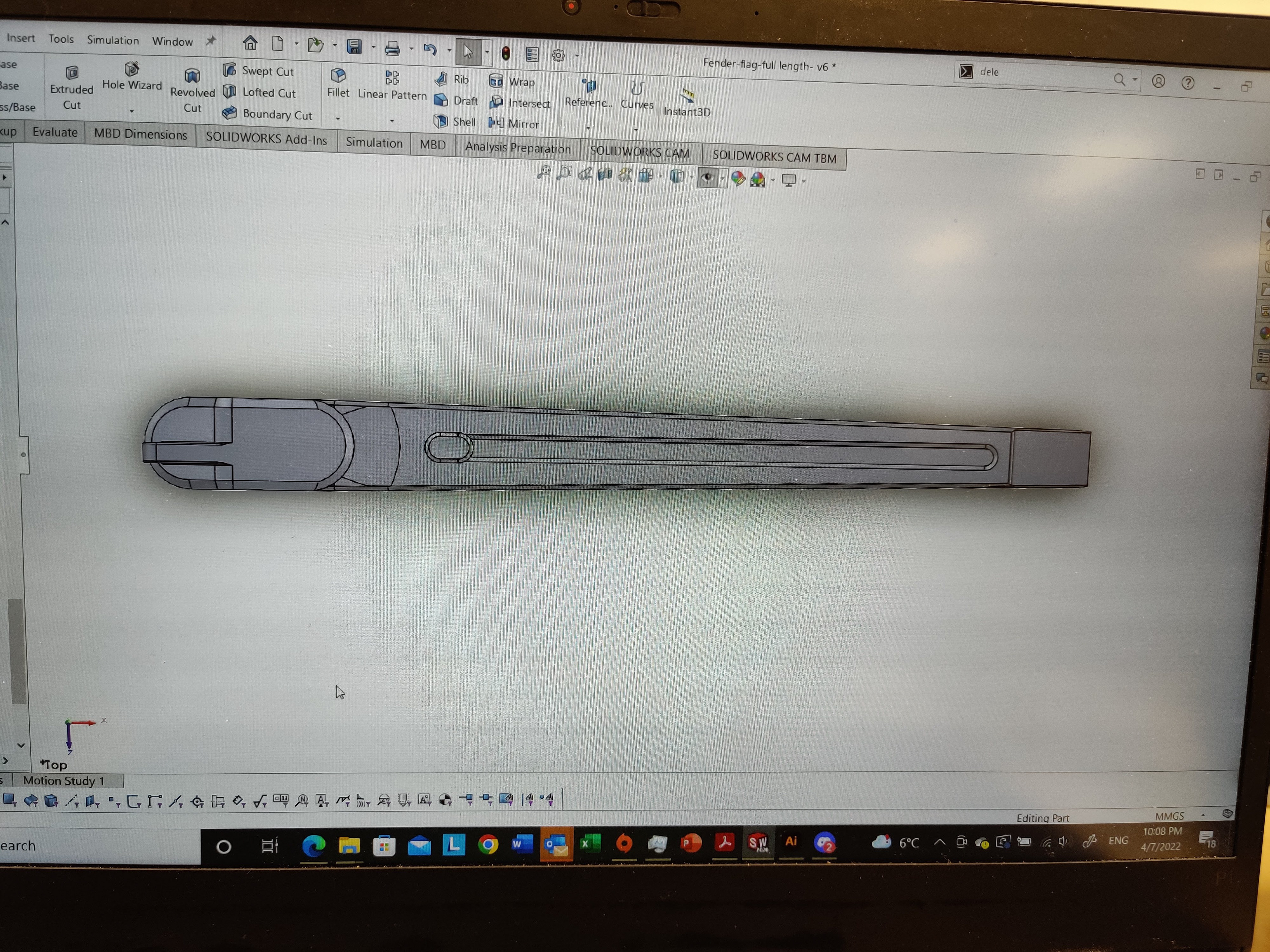

The reduced number of components also allowed for the size of the pivot area to be reduced significantly, making the design lighter and more useable. The sizes were estimated through research and visualized using Solidworks and 3D printing.

Form Development

The main inspiration for the form of the design was something that could blend in well with a bicycle, and took inspiration from modern bicycle commuter gear. This meant that some of the desired aesthetic qualities were:

Modern, Durable, Streamlined, Sleek, Lightweight and Fast.

3d model

To communicate the scale and appearance of the final design physically, 3D printed models were made. The first, less functioning model was sanded and painted to better reflect the intended materials. The second model was better planned out and designed to be able to move, to easily demonstrate the purpose of the product.

Both models were made using Solidworks, and split into smaller sections due to the size of the design. These sections were then 3D printed and assembled.

Ensuring the print can be attached to the bike

The parts were printed in small sections

The printed sections were then assembled

The model was glued together and painted

Solidworks modelling of the second model

Printed parts of the second model

The mounted model

Details of the pivot joint

This model could demonstrate motion

The final result of the second 3D printed model. Some of the printed sections were not glued together for ease of storage.

final design

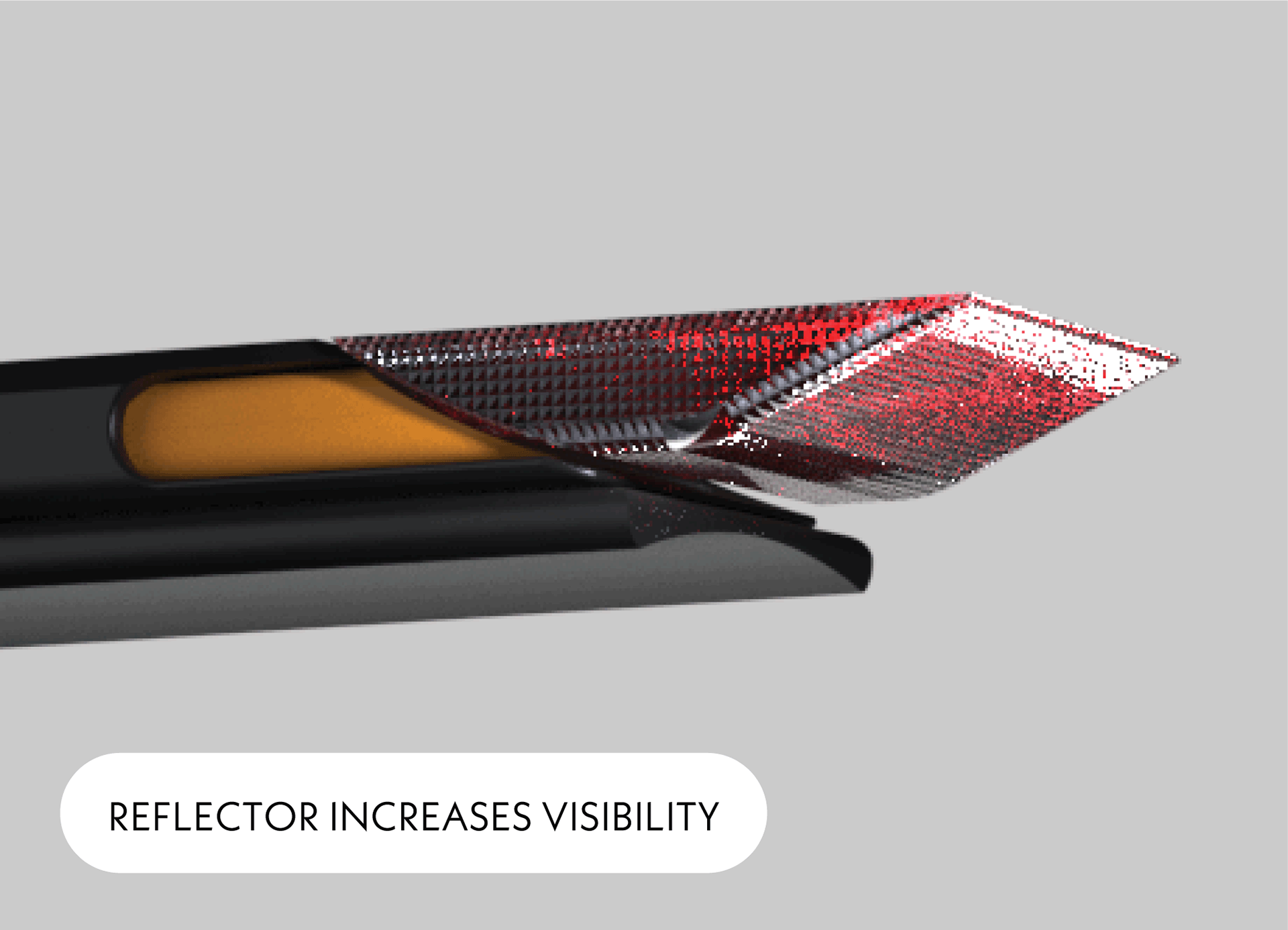

The final design is an attachable rear bicycle fender that is equipped with an extendable horizontal safety flag. Being spring loaded, the user can open the flag before getting on roads that they feel that cars get too close to them, enabling them to communicate to cars that they should keep a safe distance when passing.

This design reduces the problem of bicycle commuters on the road feeling unsafe due to cars invading their personal safe space by being a user friendly horizontal safety flag, that can easily blend in with the bicycle as a rear fender when not in use.

improvements

- Running out of time meant that I couldn't integrate the front mount control. If I could add to the design, I would do that using cable systems similar to how bicycle brakes work.

- Try to have real world tests with different materials, especially to more accurately determine how the extended flag section would work. This was made difficult due to COVID-19 restrictions.

- Better mount design to account for the product, as it is heavier than a normal rear fender. To reduce vibrations and wobbling, the mount may have to be designed accordingly.

- Would perform user tests while actually riding a bicycle to gather better data and therefore more accurate insights.