Project Summary

The brief for this project was to make a coffee capsule holder for a specific target market or client.

I chose my client to be Shell Oil, and to design the product for one of their kitchens in my mother's office.

The final product was able to store up to 60 Nespresso coffee capsules and a few other small items such as sugar and sweeteners.

Project Duration: October 2016- April 2017

Key Skills used: Concept sketching, Woodworking, Prototyping, 3D CAD modelling, Laser cutting

Key Apps used: Microsoft Powerpoint, Sketchup

Situation

This product was designed for a Shell Oil office which was primarily white and red. This fact will affect the colour scheme of the product to allow it to fit in.

After analyzing the clutter, I added a specification that the product should be able to hold a few coffee other related goods as well, due to the space it would take on the counter.

The environment the product was designed for. This shows a few of the items on the counters.

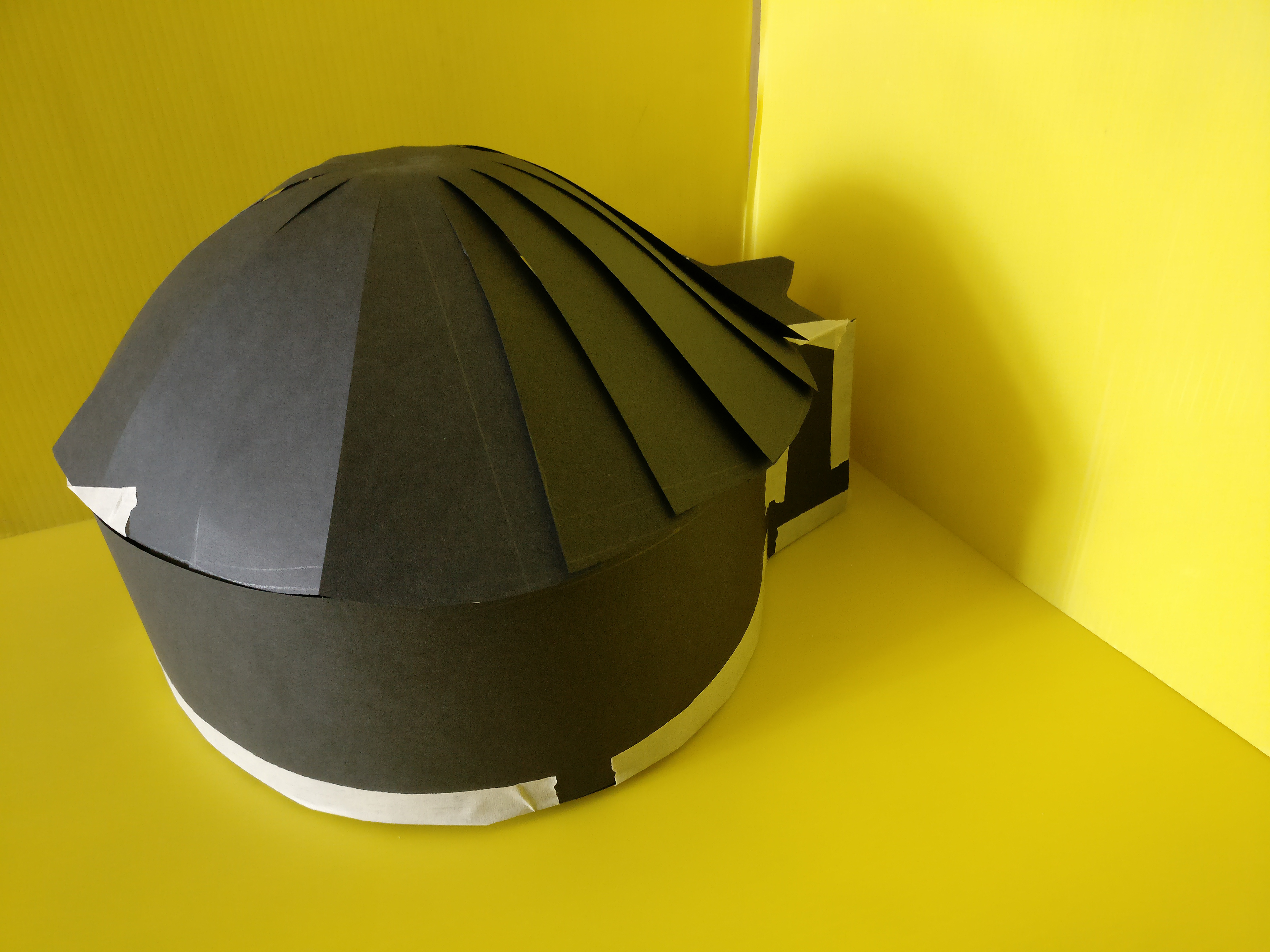

Simple modelling

After a number of ideation sketches were done, models showing simple basic forms of designs I decided to develop, were made from card-stock.

From this stage, I moved on to a final idea and went into making it.

Product plan

Here I sketched an exploded view of how I envisioned the product being put together.

This was useful in terms of planning my actions on how to make it.

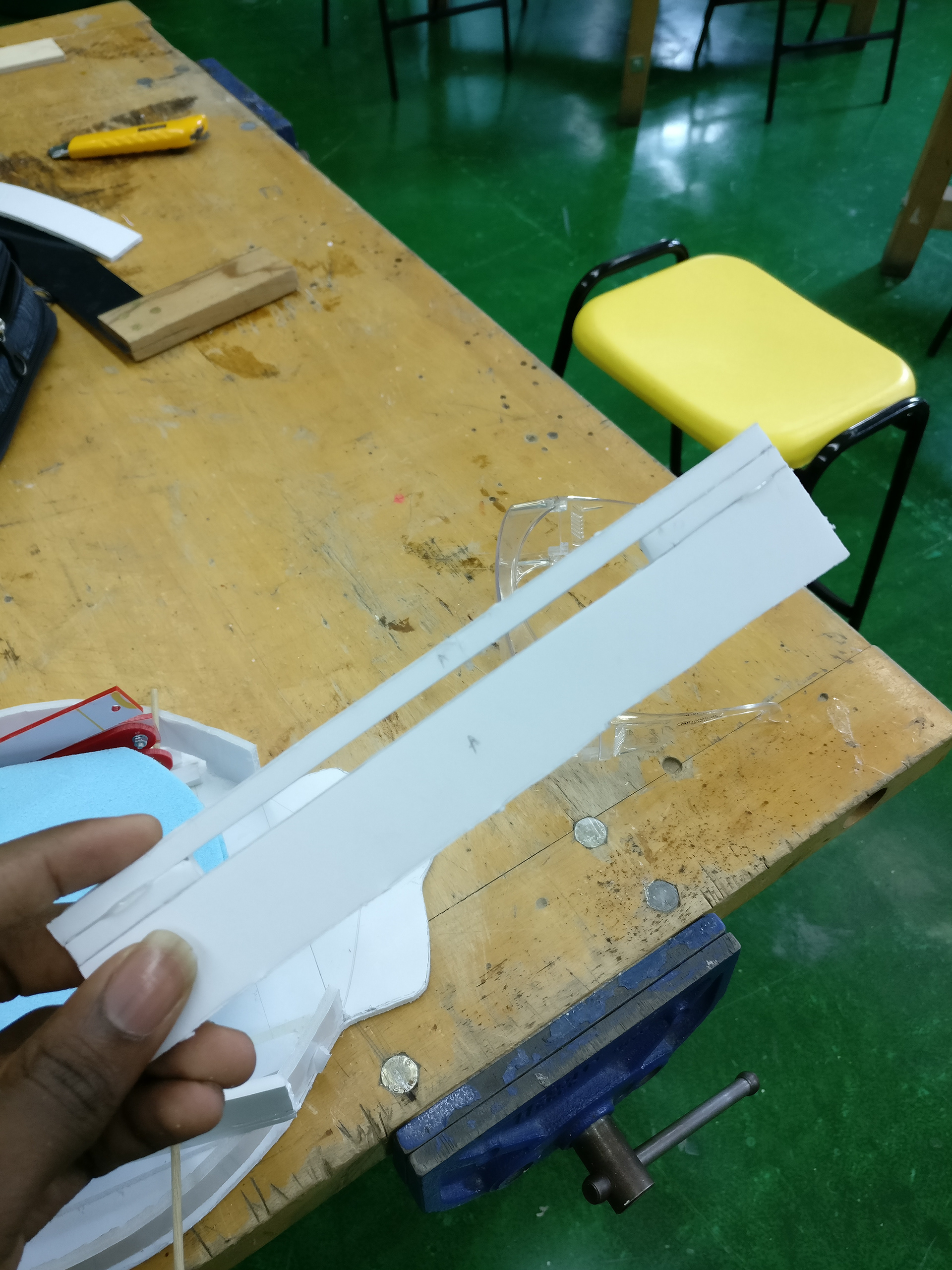

Making the Product

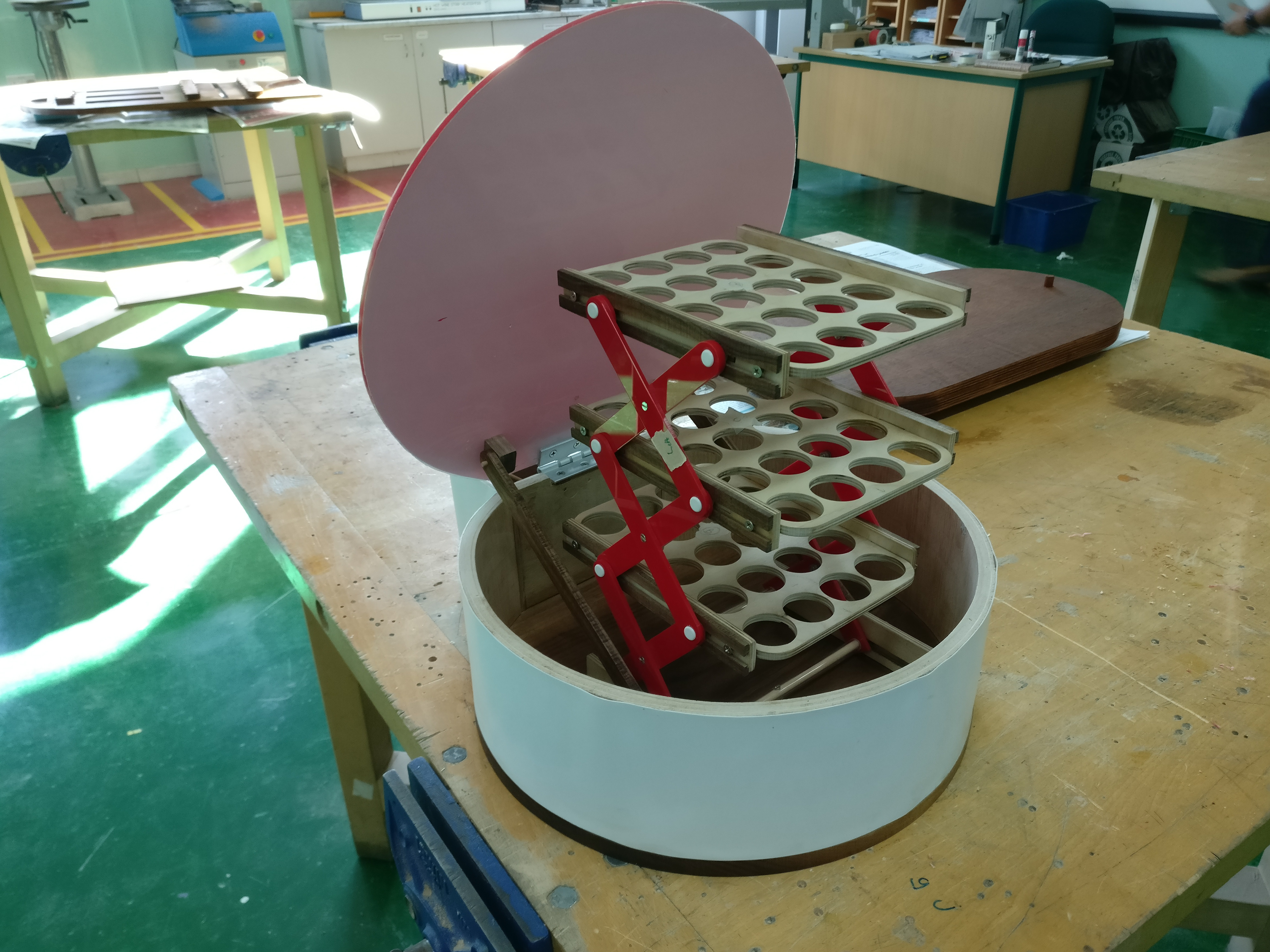

Making the final product involved a lot of testing, especially because of the mechanism.

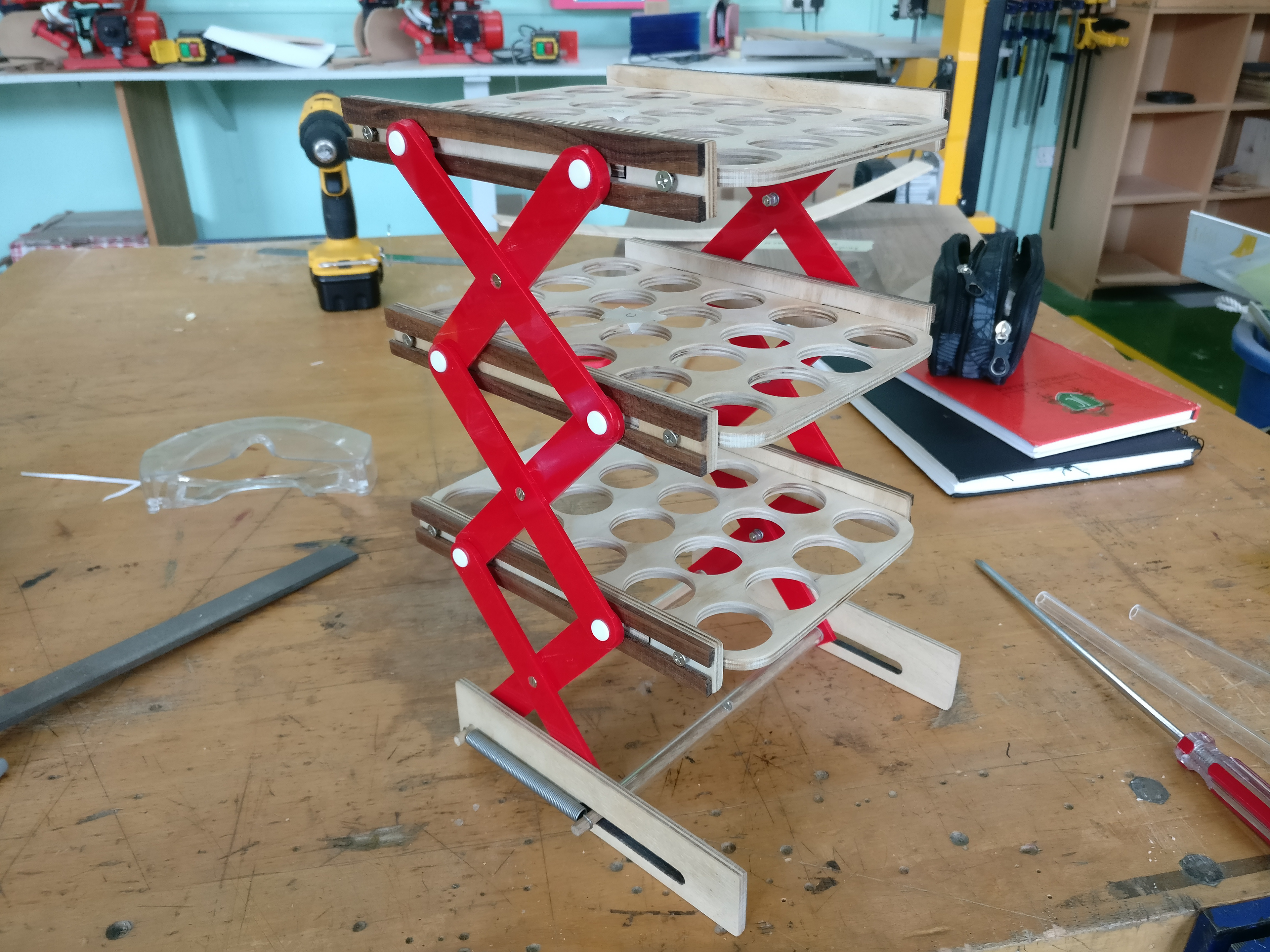

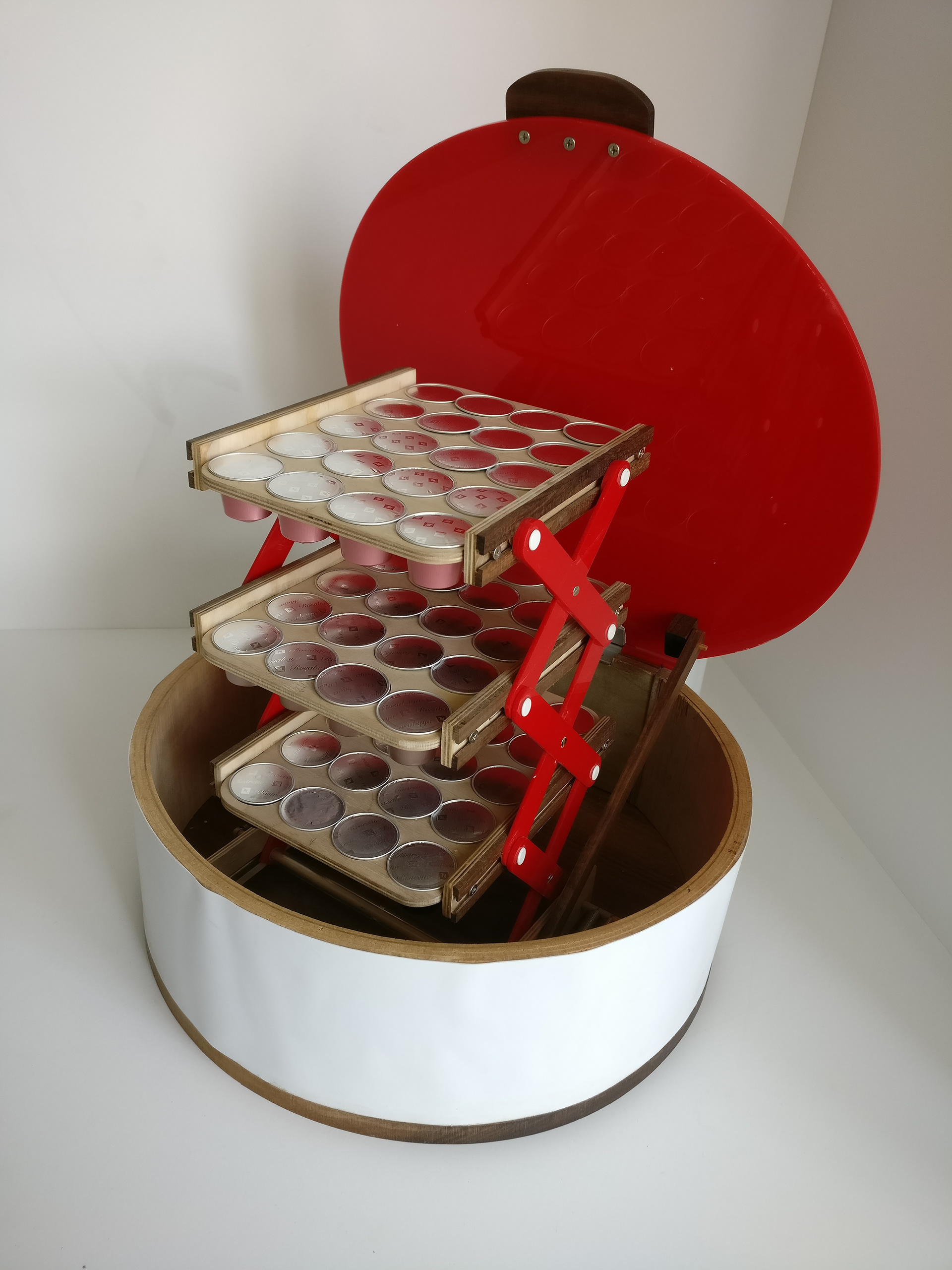

The body was finally made out of plywood laminated with white PP sheets, with a walnut base, and a red acrylic lid.

The mechanism featured acrylic double pantographs and three plywood trays (up to 60 capsules total), with walnut lined tracks.

Started off with the basic form, testing the curve radius with plywood

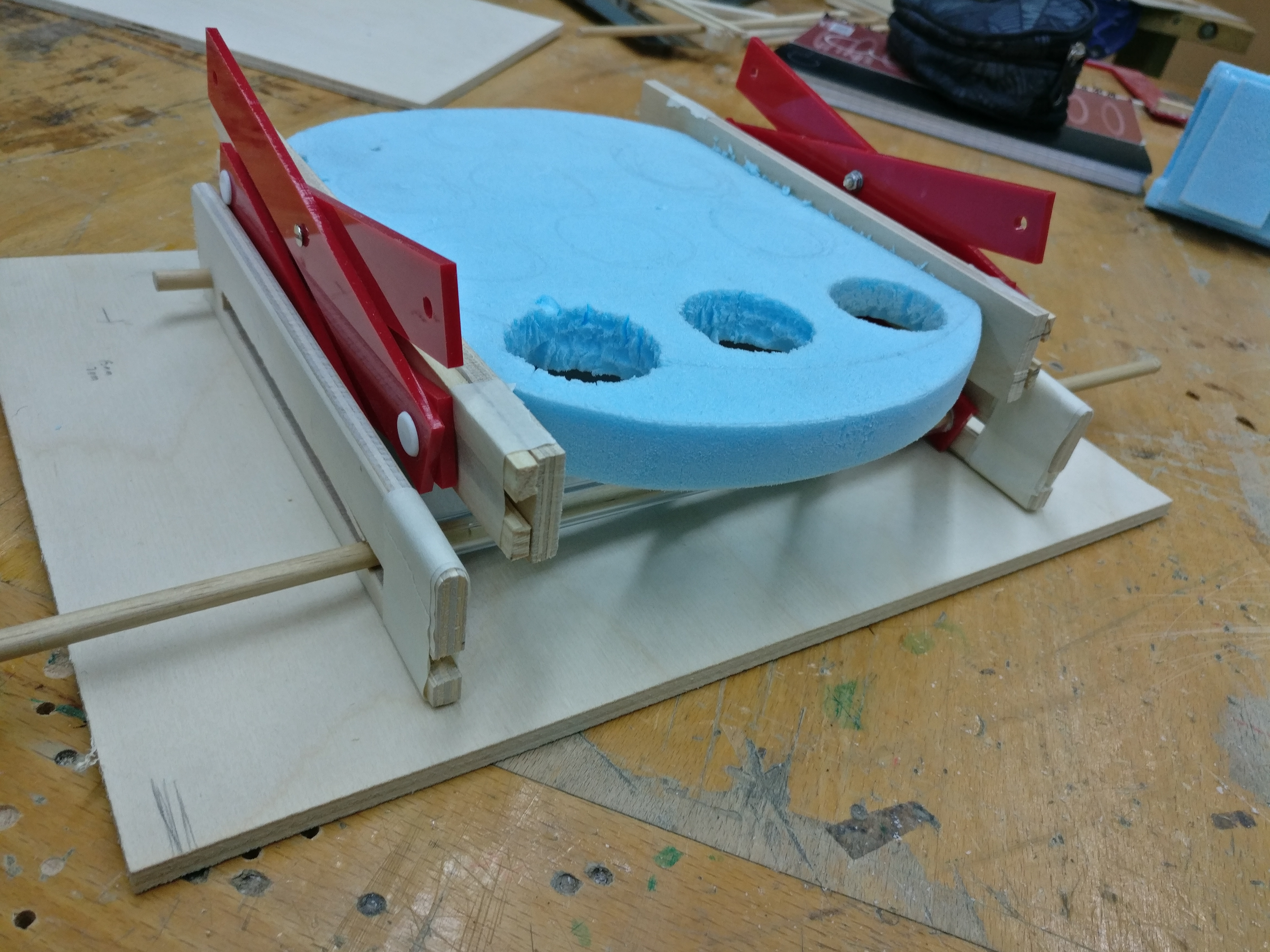

Tested the double pantograph mechanism and found that thin parts were needed

Figuring out how to line up and secure the base

Decided that rails would be a good option

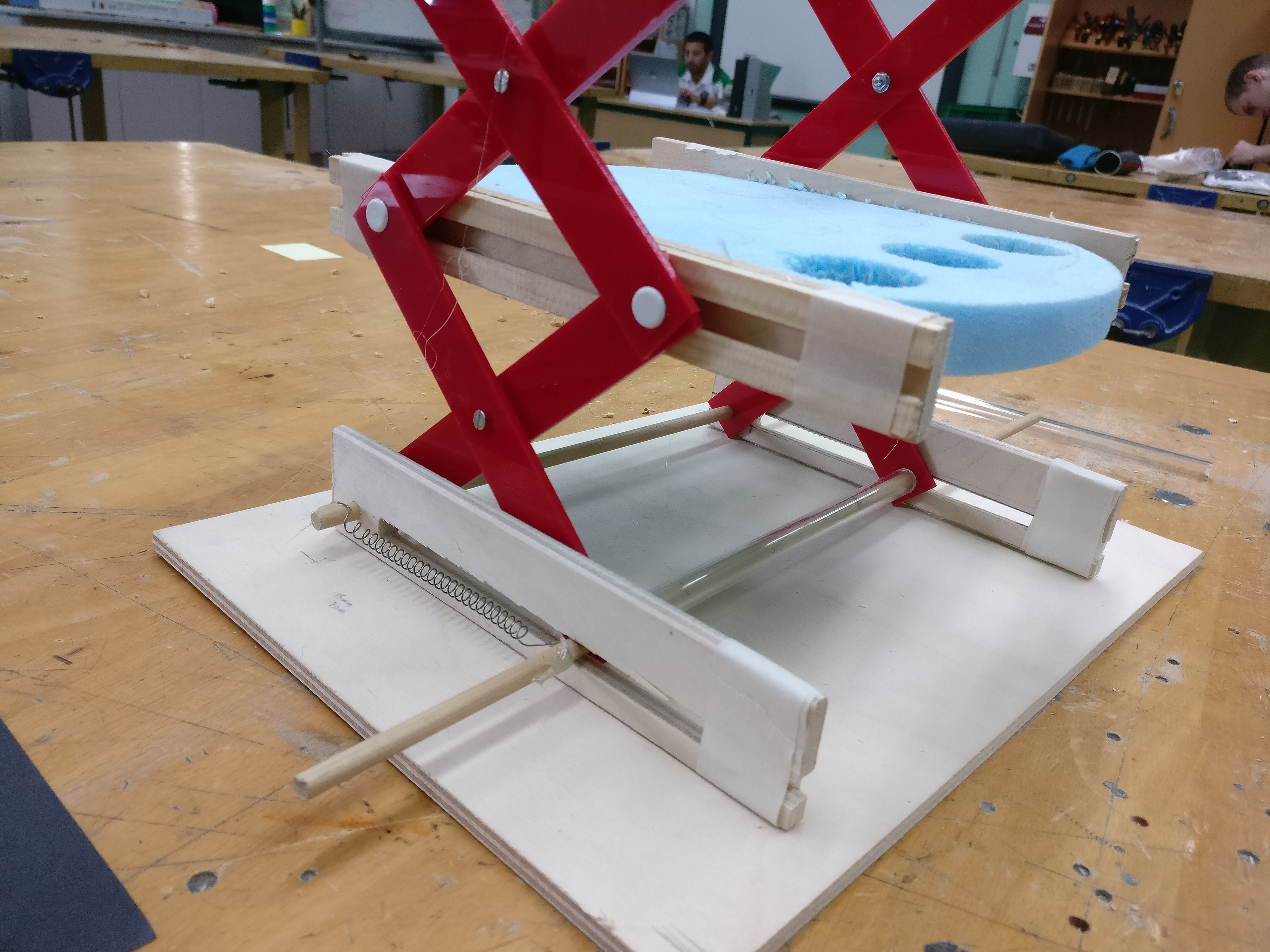

Made stronger rails from plywood

Used stronger crossbar dowels within an acrylic tube to keep the mechanism straight

Joining trays to the mechanism required more tracks for mechanic motion

Added springs to allow the mechanism to pop up when lid is opened

Final mechanism with improved parts

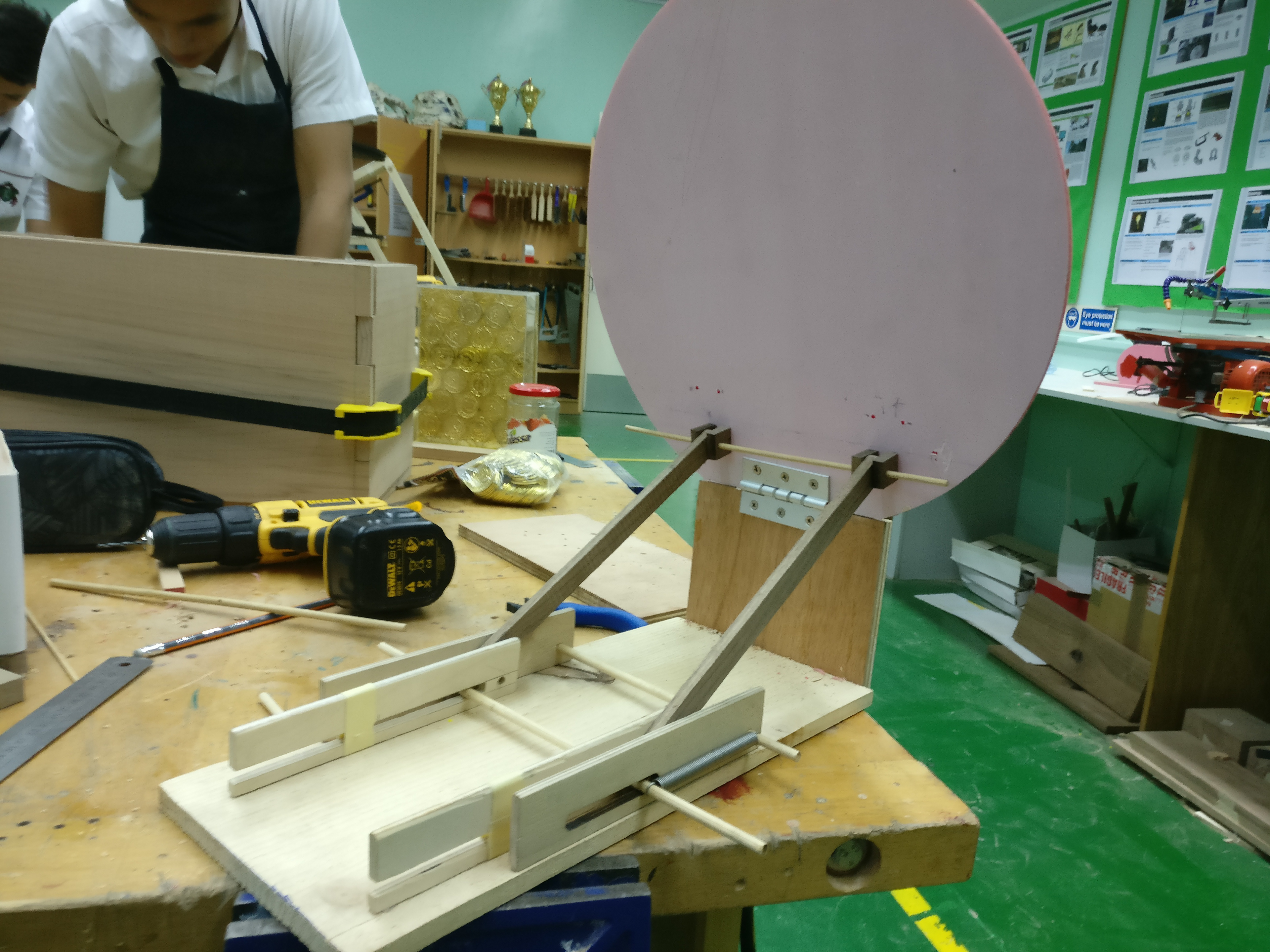

Testing the closing mechanism to make the trays collapse when the lid is closed

Forming the round form of the design

Assembled product

Added the hinge for the acrylic lid with a basic hinge

Added the connecting rods from the lid to the base of the mechanism.

Final CAD model

This was done on Sketchup and it helped me through the making process to estimate dimensions of parts, especially the closing mechanism.

Final Product

The finished product is shown along with a video of the mechanism at work

The finished product with 60 Nespresso coffee capsules