Project Summary

The brief was to make a product with a rotating mechanism.

I chose to design and make a TV stand with a rotating platform to replace an old one in my house.

It would have a remote controlled rotating platform to allow the user to remotely turn the TV screen to face them without the need to get up after getting comfortable.

The client for this project was my sister, who I regularly referred to when making decisions during the process.

Project Duration: September 2017- April 2018

Key Skills used: Research, Concept sketching, Presentations, Woodworking, Prototyping

Key Apps used: Microsoft Powerpoint, Sketchup

Ideation and development

Various ideation sketches were made, then five were picked by the client to further develop.

It would be from these five that we would pick a final design to move on with.

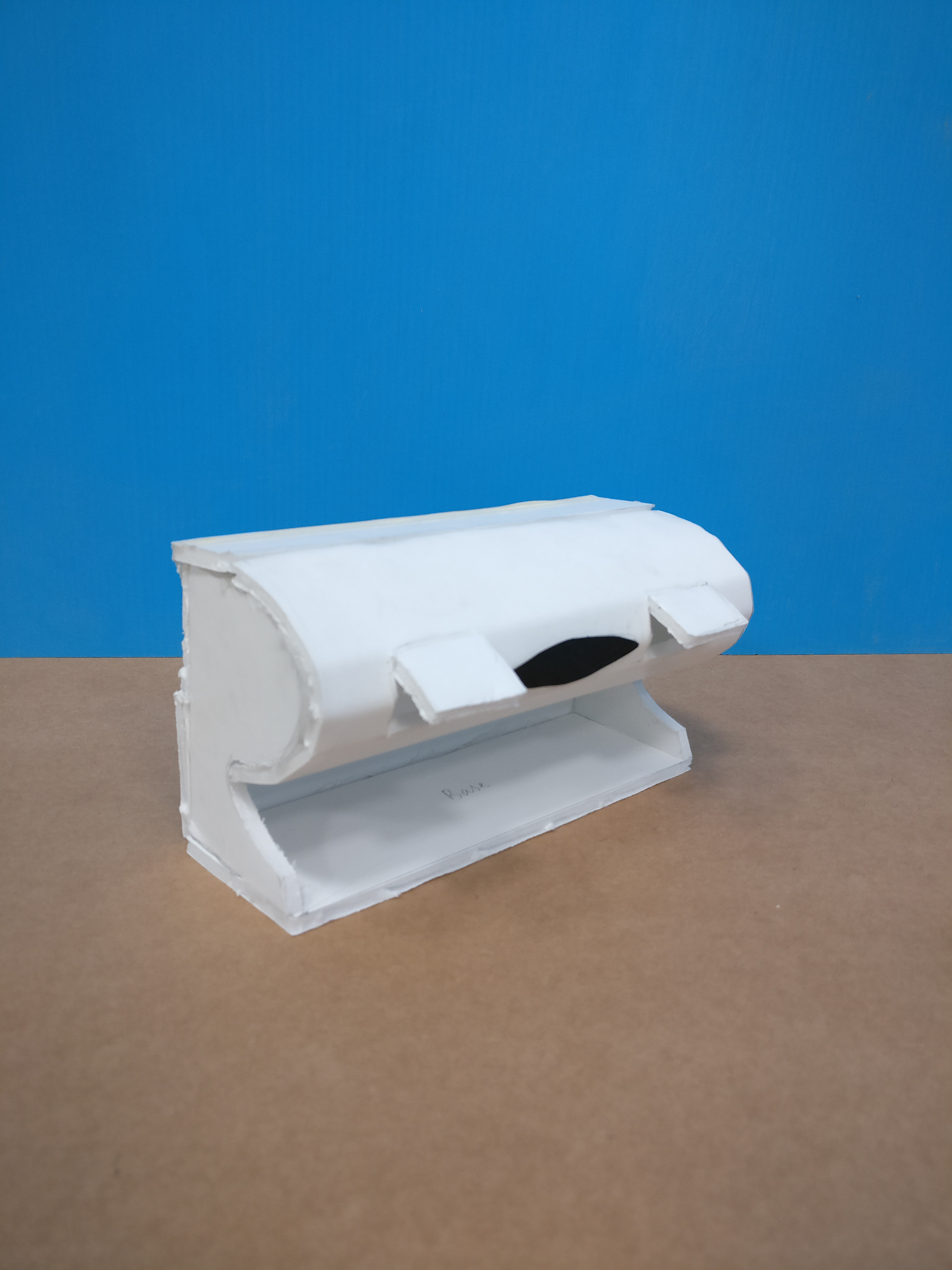

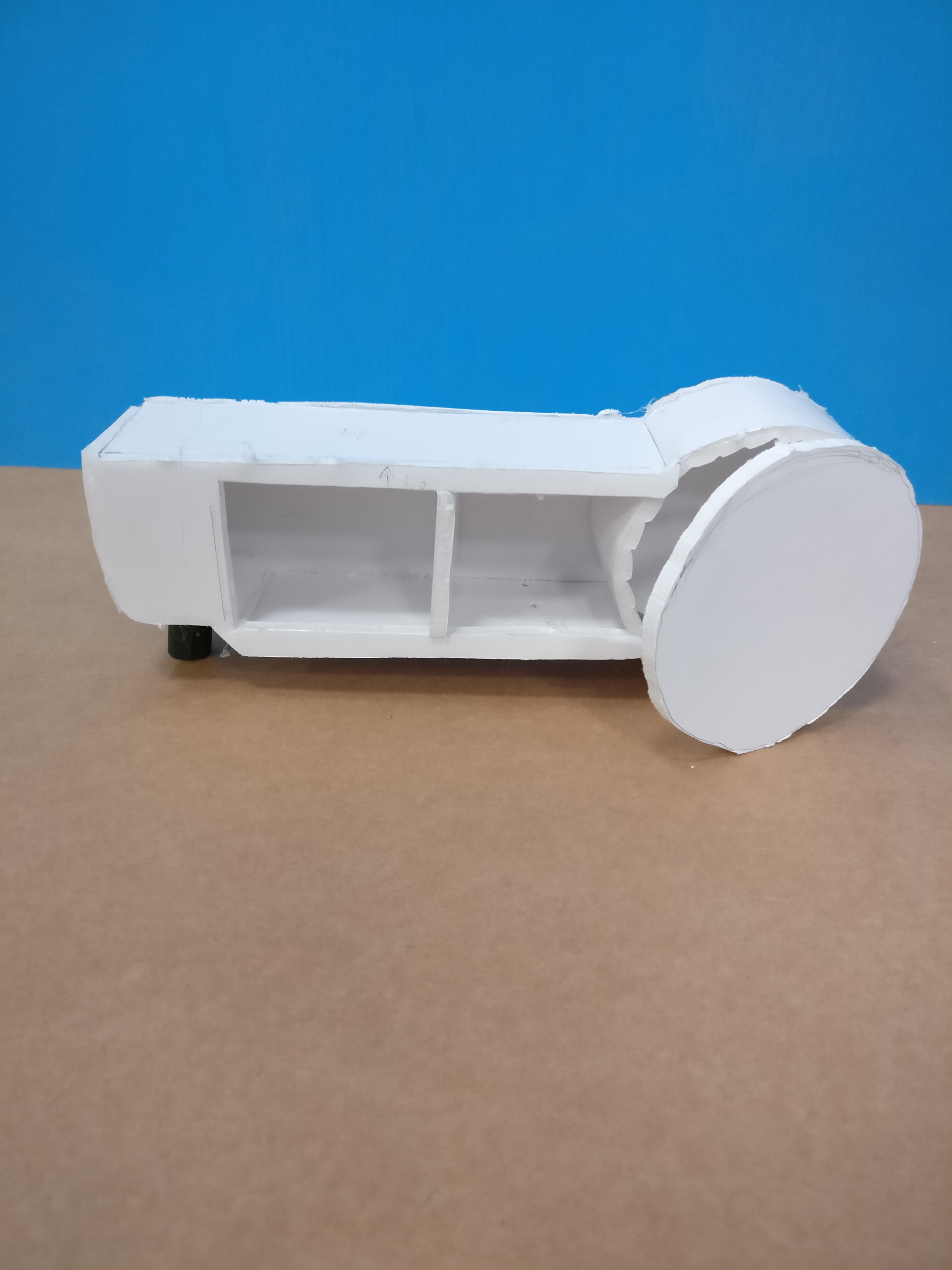

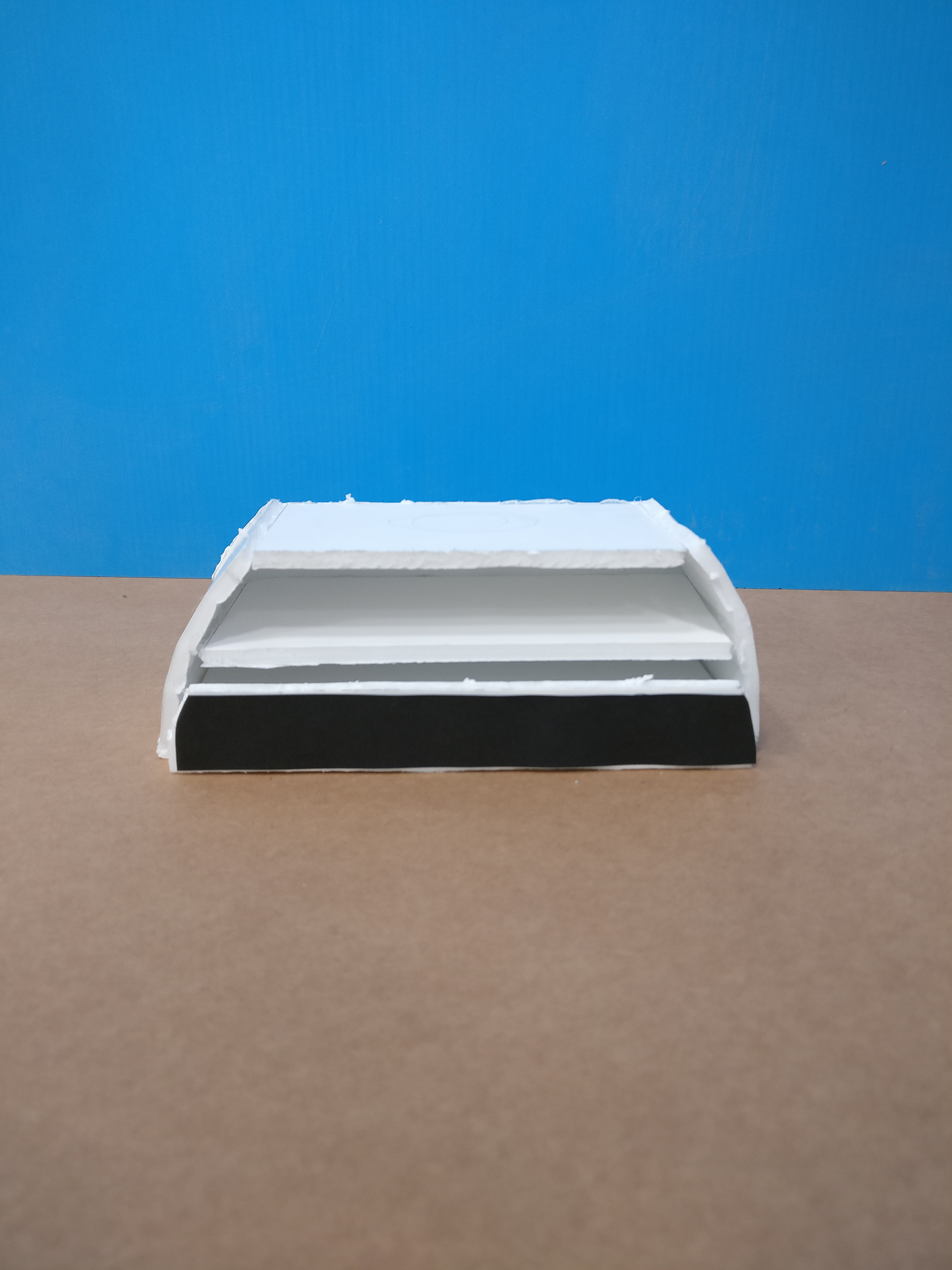

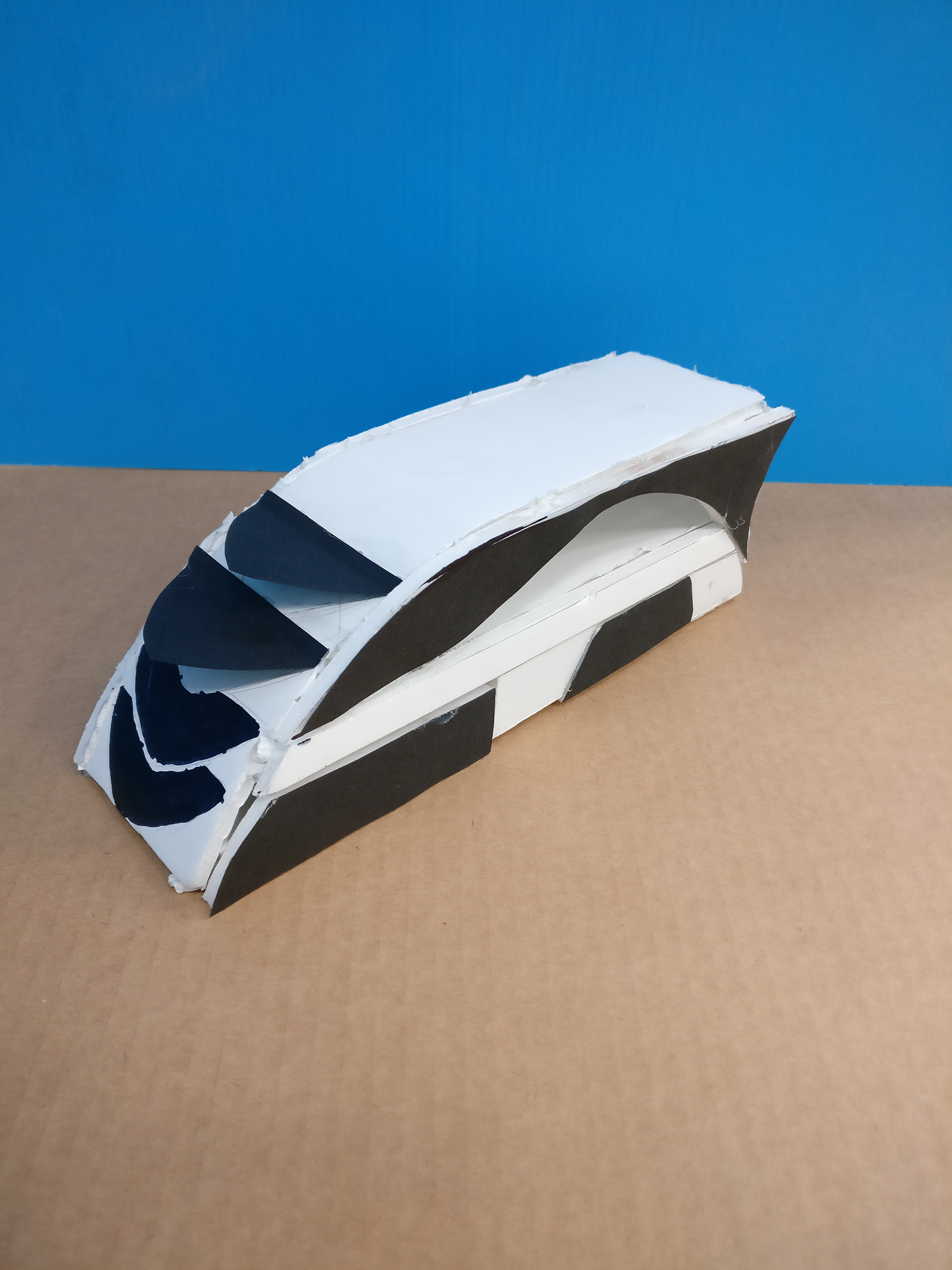

Initial modelling

This was a process I went through to further evaluate my initial ideas and help me decide on what to move forward on by physically seeing the models of the designs, and giving me a rough idea of how they could be made.

This process was done using foam board and the 3D modelling software Sketchup.

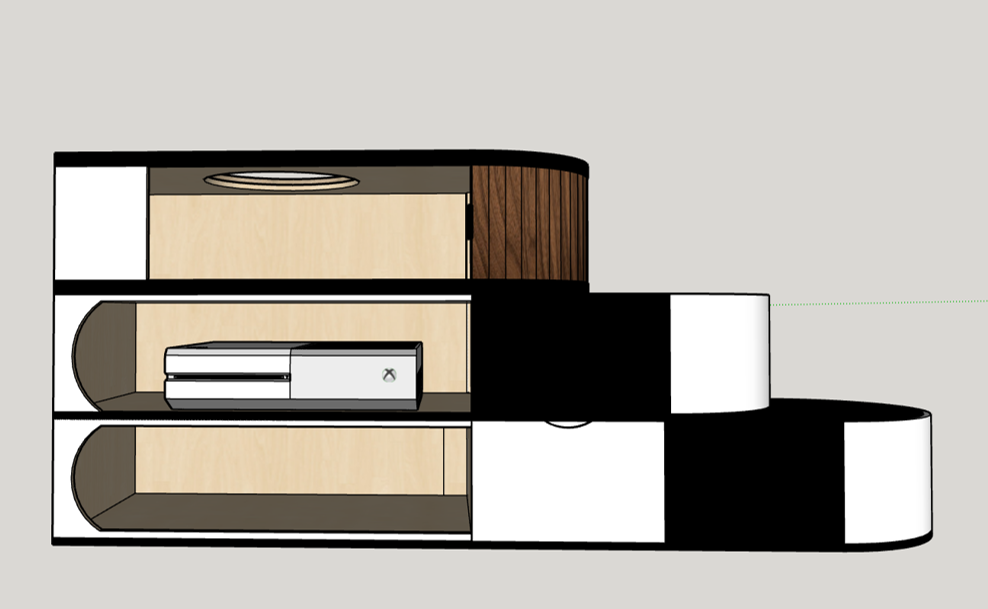

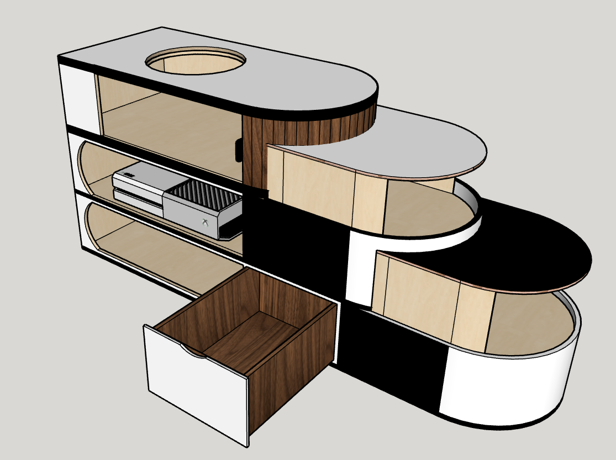

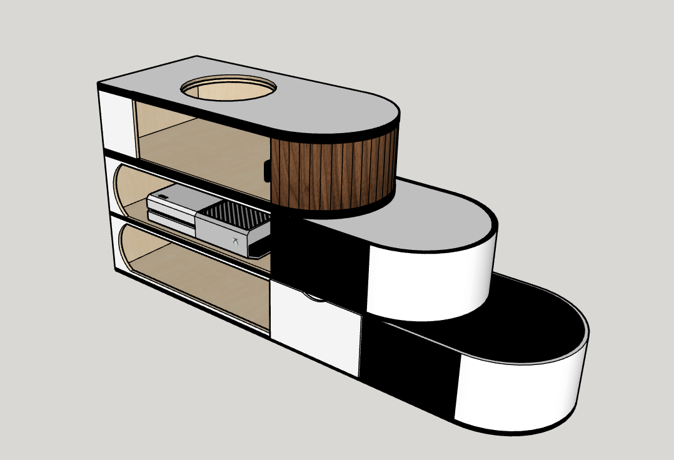

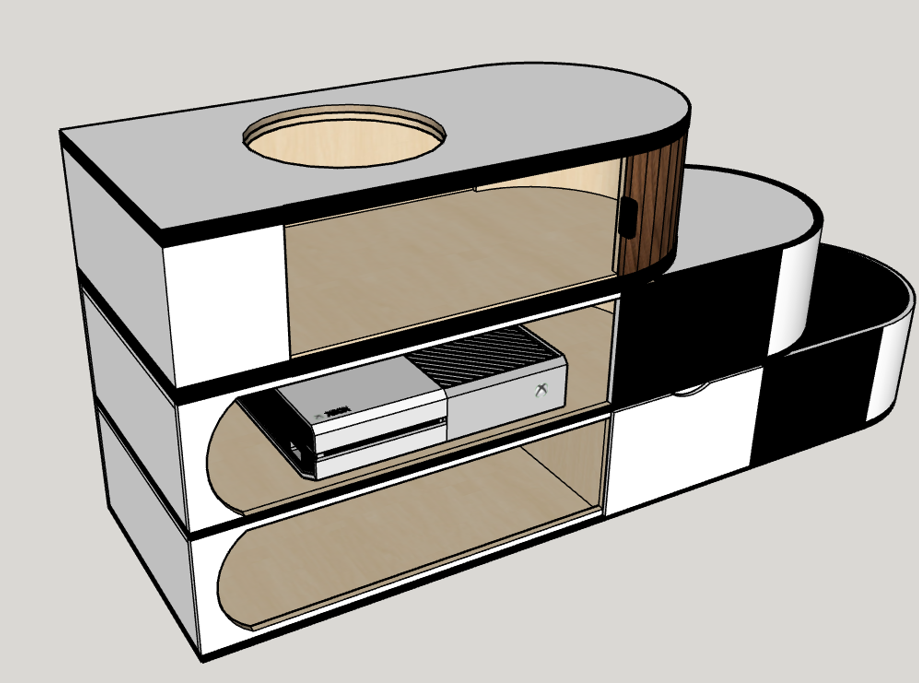

Final design

Through my development process, the client picked a final design.

It was modeled in greater detail on Sketchup to give me an idea of the colours and proportions I needed.

Final design would feature two pop up storages and a drawer for small appliances and games

There would be two layers for holding game consoles or TV decoders

The top layer is dedicated to the rotating mechanism

making the design

Making this TV stand was a long process filled with many challenges.

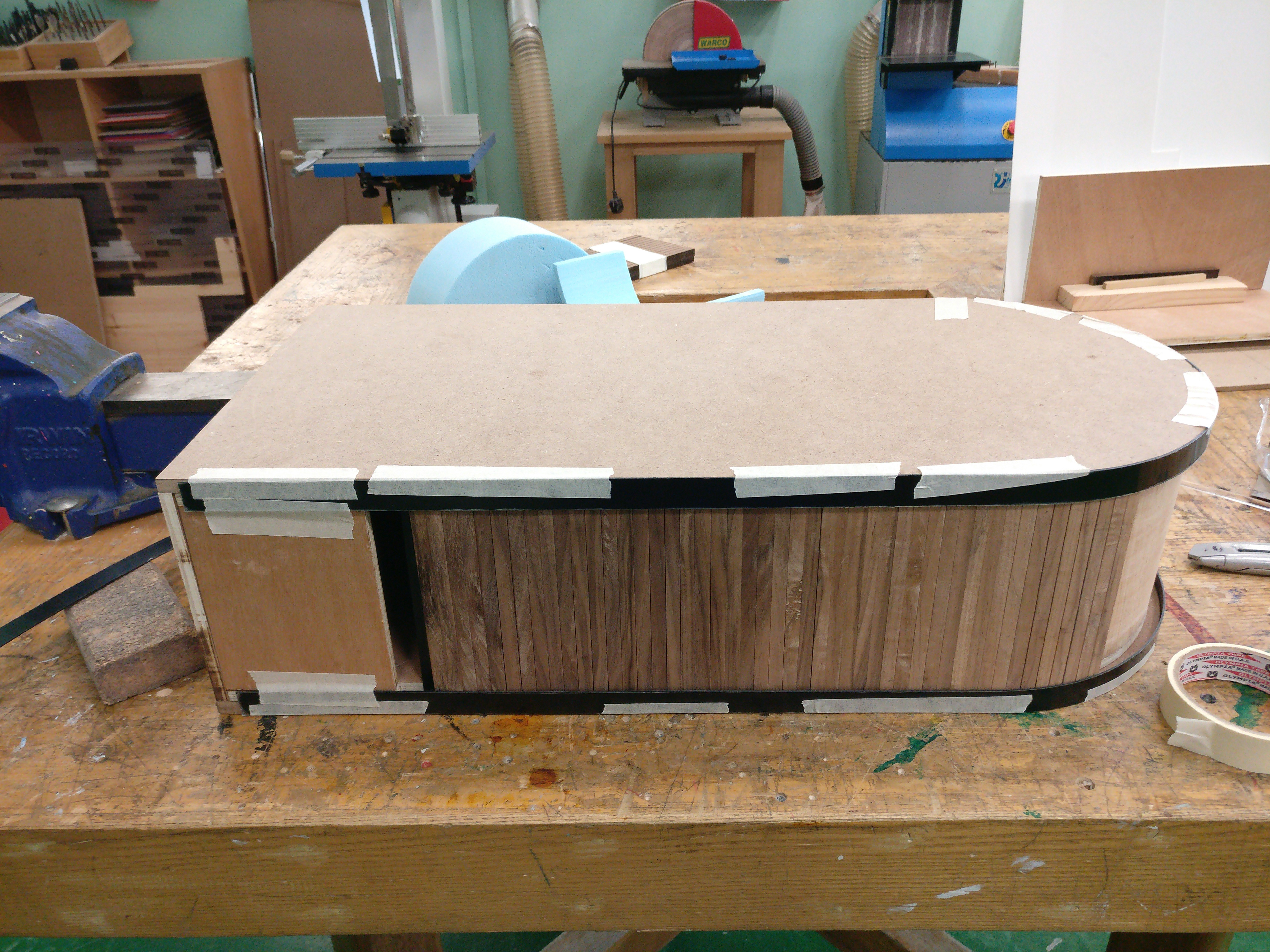

The body of the TV stand was made with a combination of MDF wood and plywood, finished with sheet HIPS as a laminate.

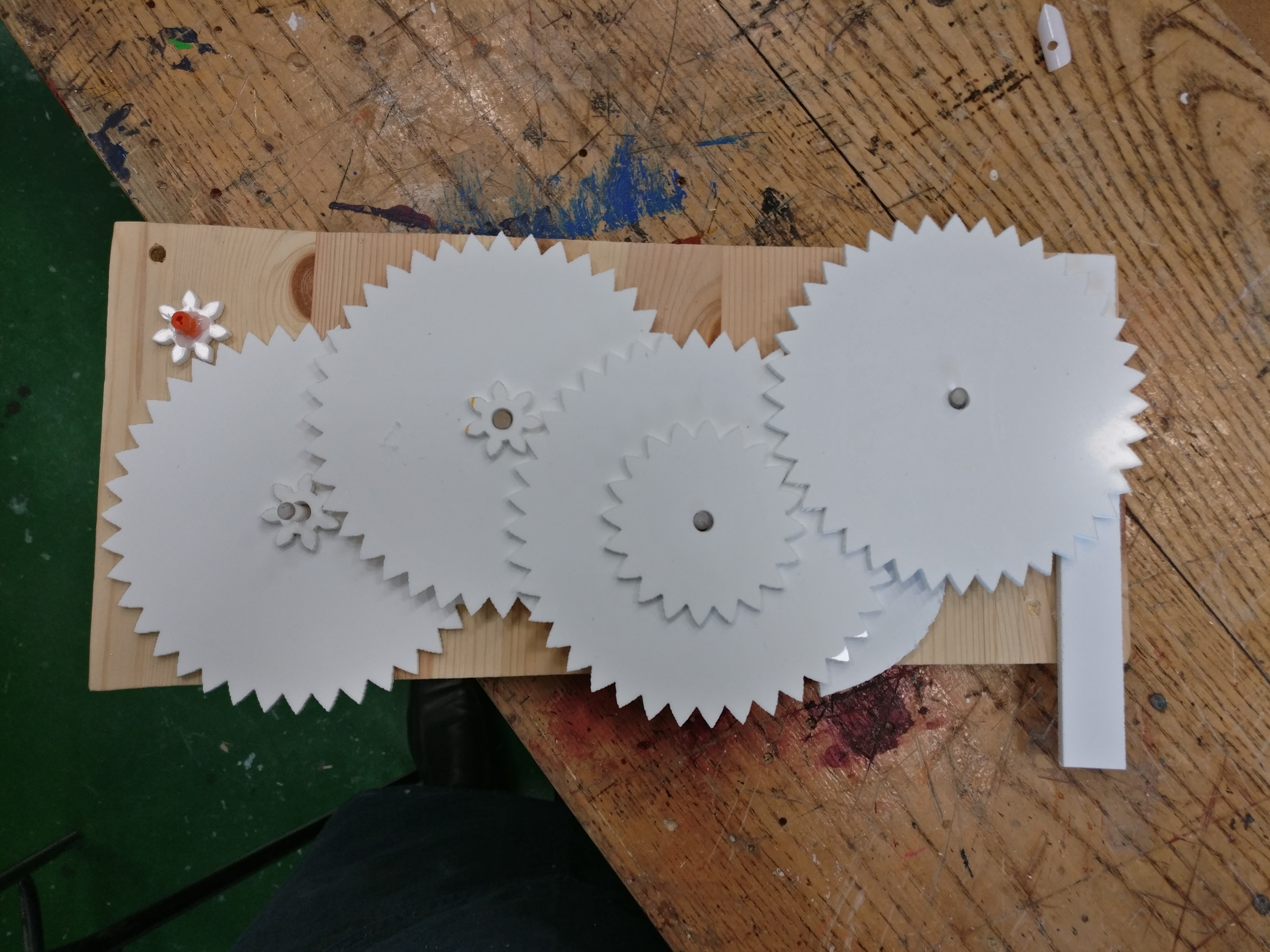

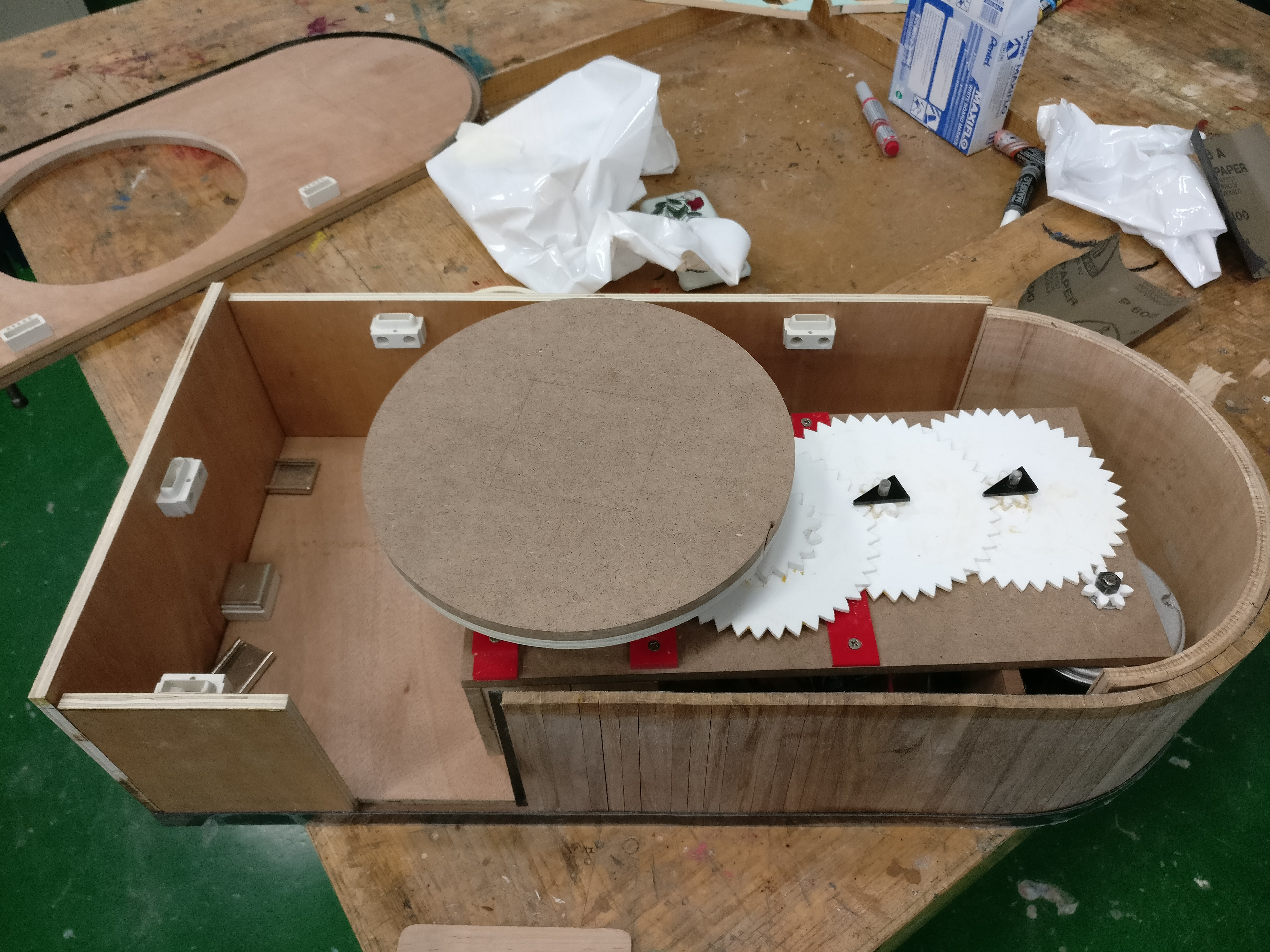

The gears were made out of acrylic sheets, which weren't ideal but it was the cheapest material available (ideal material would be nylon).

The sliding door and drawer were made out of walnut wood to add a more premium quality to the design, and because it is easy to work with and machine.

A small model to give me an idea of how the pop up mechanism would work

Initial model for the sliding door

Using an online gear generator, I got a gear layout and laser cut it out of acrylic

Making the curve of the top layer

Ensuring the parts of the sliding door of the top layer fit

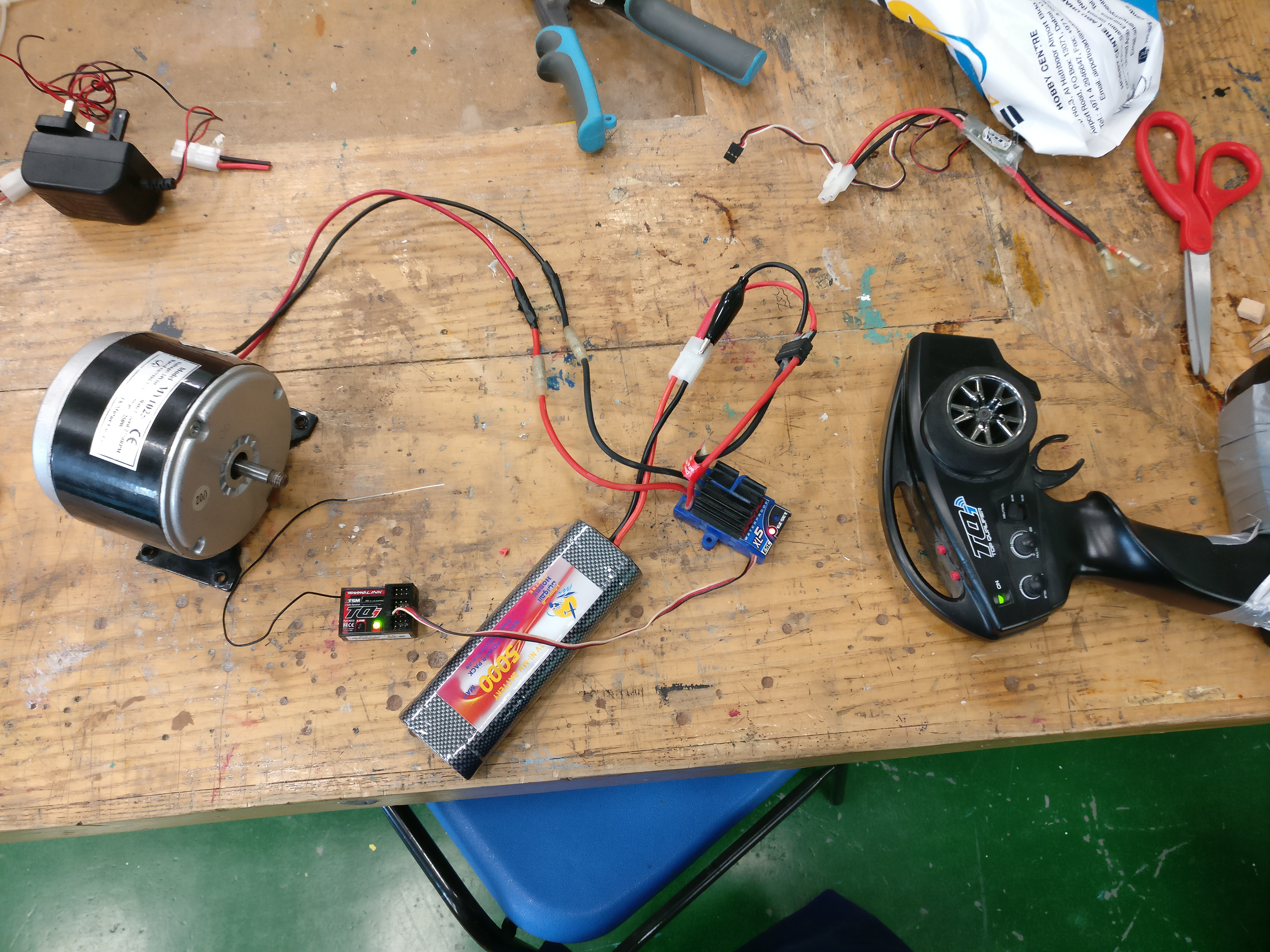

The electronics: A motor, an ESC, a receiver, and transmitter from the remote

First and second layers complete. They are made of MDF wood and plywood for the curves

The wooden drawer is made out of walnut wood with a black acrylic base

The full gear setup with the rotating platform

All the three layers assembled

The wood was finished by laminating the surface with HIPS sheets

Context shot

Showing a user interacting with the TV stand in the intended room.

Drawer in use

Sliding door to easily access mechanism for maintenance

Pop up storage could hold remotes or controllers